Bonded abrasive products are breakable and shall therefore be handled with utmost care. The use of damaged, improperly mounted or improperly used abrasive products is dangerous and can cause serious injuries.

Delivery, Handling and Storage

- Abrasive products shall be handled and Trans ported with care.

- Abrasive products shall be stored in such a manner that they are not subjected to mechanical damage and/or a high level of humidity.

Selection of the Abrasive Product

- Information on the label or the abrasive product, as well as restrictions of use, safety indications or any other instruction, shall be followed.

- Wheels used on any machine shall only be of a type for which the machine is designed.

Inspection

- Prior to mounting, all abrasive wheels shall be visually inspected. Wheels which show evidence of cracks, abusive handling or abusive storage must not be mounted.

Operating Speed

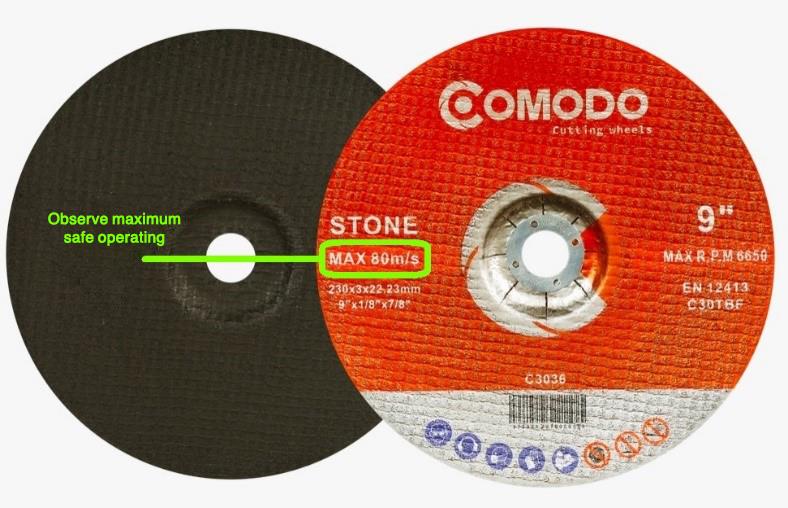

- Machine speed shall be set and measured to make sure that it does not exceed the maximum operating speed designated for the abrasive wheel .

Observe maximum safe operating speed

Mounting

- The mounting of abrasive wheels shall be carried out according to the instructions provided by both the wheel and the machine manufacturers.

- Mounting of abrasive products shall be carried out by a qualified trained person.

- Flanges and adaptors shall be checked for flatness of bearing surface. Sprung or warped flanges or adaptors, or those which are not clean and free of burrs, must not be used.

- The spindle end nut shall be tightened only enough to drive the wheel and prevent slippage.

- All newly mounted wheels shall be run at operating speed for at least ten seconds before applying to workpiece. No one shall stand in front of or in line with the wheel, and the maximum safe operating speed must not be exceeded.

- In the case of strong vibrations during the test run, the machine shall be stopped, the tightening nut released, the wheel remounted, and the machine restarted. If the strong vibrations persist, the wheel must not be used.

- Arbor hole size: Abrasive wheels shall fit freely but not loosely on the machine spindle. The size of the arbor hole must not be altered to fit the spindle.

Mounting – cont

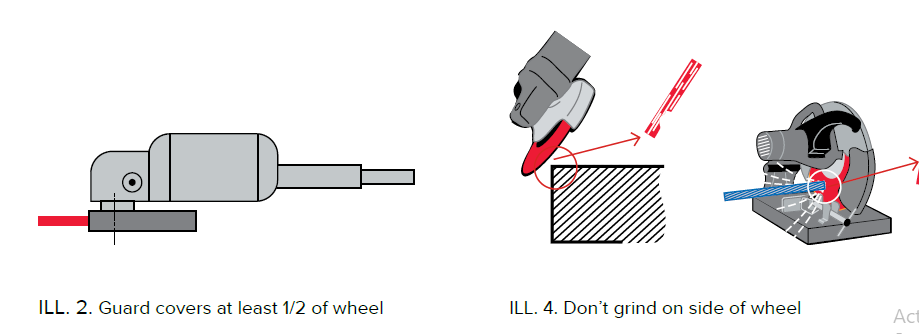

- At the completion of wheel mounting, a safety guard covering at least one half of the wheel shall be in place (ILL. 2). All safety guard fasteners shall be in place and properly tightened. Grinding wheels must not be operated on any machine which has had its safety guard removed.

Operation

- Care shall be taken not to apply excessive pressure between the abrasive wheel and the workpiece, and to prevent the machine from slowing noticeably or the workpiece from becoming overheated.

- Grinding must not be performed on the side of the wheel.

COMODO ABRASIVES

Personal Protection

- Safety goggles or safety spectacles shall be worn by all personnel exposed to grinding operations.

- Where necessary, additional personal protective equipment shall be used, such as face protection, ear protection, respiratory devices, aprons, protective footwear, and protective gloves .

Stopping the Machine

- Before placing the hand-held grinding machine on the workbench or floor it shall be ensured that the abrasive wheel has come to a complete

SAFETY ICONS